How I Wrote A Bowl

I'm learning words and clay work the same.

I’ve never held a bowl made for hands.

At least I assume… Cause bowls are shaped for what goes inside. Consider the cascading walls of a ramen bowl. The shallow flare of a catch-all, short all around for jewelry and keys. Ceramicists obsess over depth, glazes, and clay bodies, but rarely the hands that hold it.

That’s funny, knowing most uses of bowls start and end at our fingertips.

One year into throwing more accidents than flawless bowls, I ramped into lucidity. Every bowl I made was sittin’ sideways, slouched as people in the stu smiled at the ‘character’ of my work. A shorthand slight for nice try.

A solo night at Bitter Root Studio, I was feeling out a bowl in the process of drying. My fingers traced these grooves I hadn’t meant to create. Resting in pockets of space. Cozy… Secure enough for me to fake spiking it like a football. Real crash out chit.

In the middle of doing a lot, an epiphany: Make a bowl for my hands, on purpose.

I had trouble sleeping that night. Tossing and turning as this objective became a paragraph.

We should make bowls for hands. Making it easy to pass potent flavors from hand to hand. A shape so ready for our hands, even washing dishes becomes a natural, fidgety act, like a child playing in water.

That text lit a spark between a close friend and I. They also threw ceramics, amongst many hobbies, in their work as an engineer. Someone with the ability to illustrate ideas with technical drawings.

Between our solo practices of throwing, I used words to add value to our tactile exploration.

The bowls need to fit like a glove, and I feel like it can happen on the walls. Rather than straight lines between 65 and 150 degrees, let’s lean into a wall we can grip. Think about where our index, middle, and ring fingers go as we reach, knowing the pinky will follow.

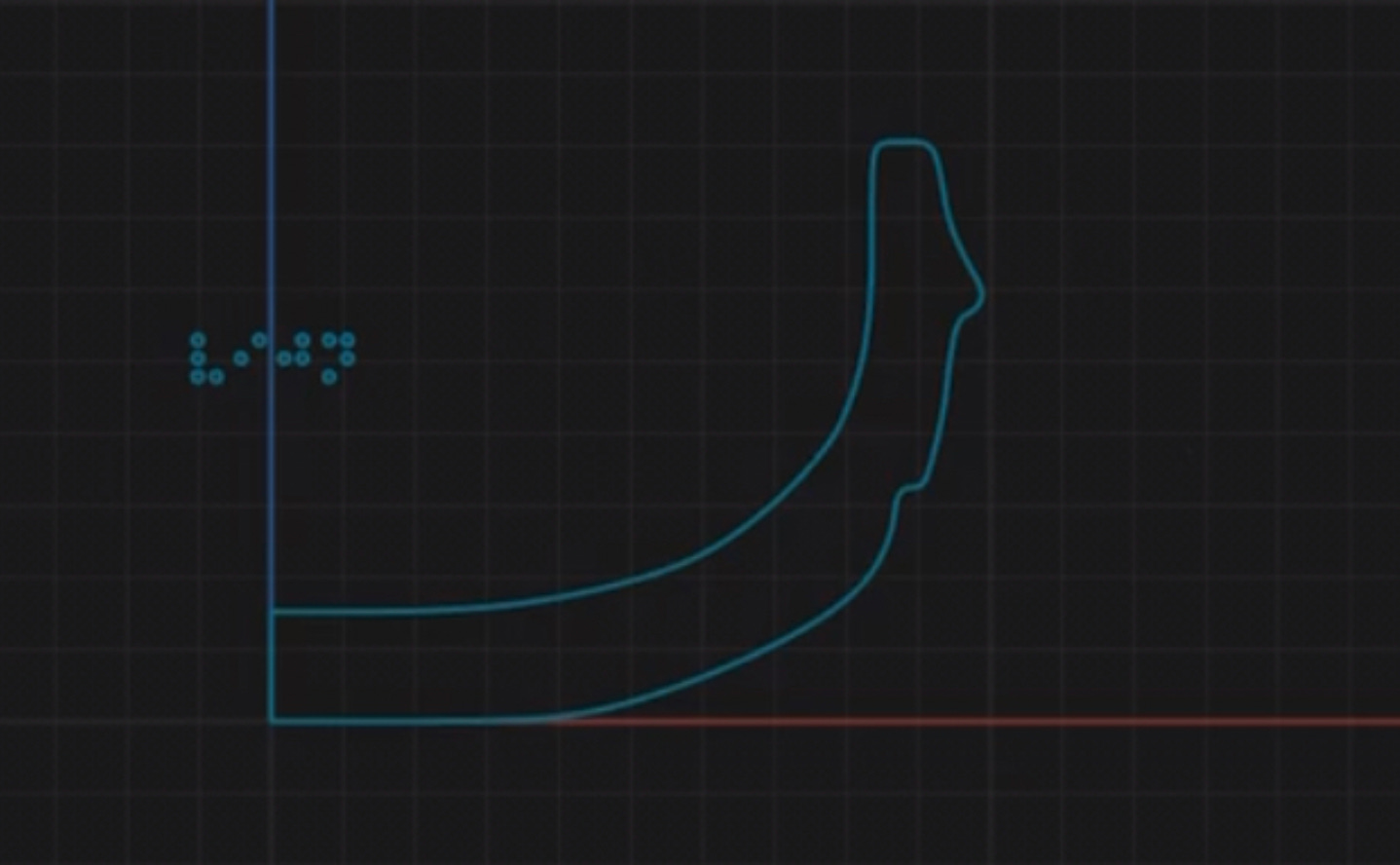

The homie saw it clear, producing about 20 CADs with various protrusions, lumps, dips, and curves. I sat for hours on my phone’s 3D visualizer twirling the cups and bowls they visualized. My eyes pulsated. My brain made sense of these shapes, guessing how’d it could actually work.

One particular approach spoke to us early.

A simple shape with two divots on its exterior, creating a Stonewall jawline from its side. Even digitally, I could sense where my fingers would fall. It felt right.

I think you did your big one here. There’s a simplicity to this wall. The double layer build sets some graft for stability. That vertical C-shaped curve should let the top and bottom of our palms clasp it for security.

One big problem: We simply weren’t ready to throw this shape. Our hands and feet couldn’t manipulate the wheel for this precision. So we pivoted.

Slipcasting became the play.

I arrived to Charlotte ready to see friends, catch Khruangbin that night, and finally… grab our bowl. Well, 3D printed. Still, real.

The high trees of a suburban neighborhood softened the afternoon beams. A delicate backdrop for what turned out to be the brightest revelation.

My friend’s friend had converted their garage into a slipcasting space. Right next to her husband’s 3D printing service. Wicked convenience we used to iterate.

I’m starting to notice there’s curves on curves. The two divots create three surfaces on the wall. Each about an inch in height. Each gives us a new point of leverage. The bottom divot curls to the bowl foot, where our pinky and ring fingers rest. The middle divot is straight for this middle finger. The top divot curls like a J, where the vessel opens up.

I tip toe’d into the backyard, as this print was handed to me.

My eyes darted. My fingers struck exactly where we wanted em’ to. As my heart raced, eye contact bounced around as we got to geeking. We made something new.

That was three years ago Plenty has changed, especially how that sequence of time shaped my perspective on language. Amidst a fluid skillset of throwing ceramics, slipcasting became a bridge to intentionally shaping something new.

Between my friend, their friends, the ceramicists of Tik Tok, and 3D printing savants, I could’ve gotten lost in their technical prowesses.

If only my own strength in words hadn’t made itself clear before I could try to find it.

Writing was my contribution to design.

Pulling references from other tactile sources to imagine new wall structures. Taking my time to put words together. Letters, sounds, and tone–guiding my partners toward decisions big and small.

As this bowl became the foundation of the Nest. the first product from our tactile design company VIJN. I saw myself clearly.

I’m a writer. Writing things into existence.

If you make things too, or been debating trying, here’s how words will help you build:

Write your references out. We hoard visuals that move us. Never let them be passive. Organize them. Make themed folders, name those mood boards. Did you know your Photos app enables captions below each image ? I didn’t until last week fr. Describe what you see in curves, colors, and materials, especially when the words have to be made up.

Describe the feelings you like. Yes, emotionally, if you want. But in our case, think texture, weight, heat. Write about objects how novelists write about characters and people. As often as you can. Simply knowing why you appreciate things will sharpen your pen, so you can bend words to your will.

Try more hand crafts. Before ceramics, I started with pants. Learning to make tech packs and patterns taught me the blueprint mindset for objects. Subtle cross pollination that walked us into 3D printing and eventually, slipcasting for bowls. Every craft showed me the tight connections of making and the tactile vocabulary across categories.

Words shape worlds. Technical skills or not, writing can be your most tactile tool.

Most thinkers and doers assume writing is only for expressing thoughts. At its most vibrant and direct, writing shapes form. Inshallah the Nest–and everything we build at VIJN–starts as language we sharpen all the way to your hands.

Writing is a design practice.

Stick with us on TACTILE. This truth stretches across every step in making things real.

This how I’m comin the rest of 2025

oh really !!!!